PRODUCTION CAPACITY: 27-2020 T/H

FEEDING SIZE: 35-360 MM

OUTPUT SIZE: 3-50 MM

Processing Materials: river pebbles, granite, marble, limestone, fluorite ore, gold ore, barite, calcite, dolomite, bluestone, glass, basalt, iron ore, etc.

Download Cone crusher PDF

Download Cone crusher PDF

Download PDF

Download PDF

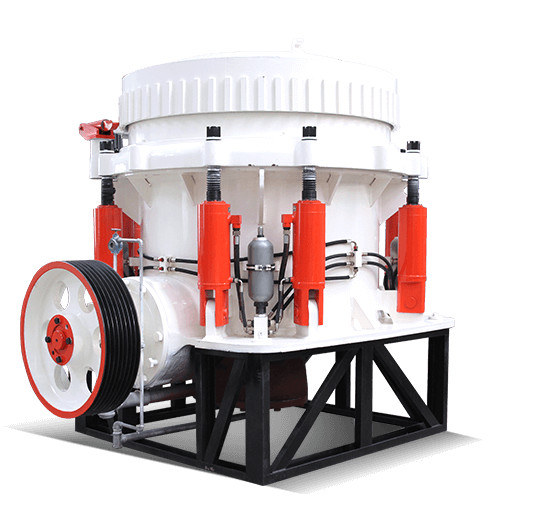

The cone crusher is a kind of stone crusher machine applied for metallurgy, building, road construction, chemical engineering, etc. It is suitable for medium and fine crushing with the features of high crushing ratio, high efficiency, low energy consumption and uniform particle size.

There are different models in HXJQ divided by different crushing principles and different particle sizes: single cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, hydraulic cone crusher, Symons cone crusher (compound cone crusher), and spring cone crusher. At present, the most advanced one is the single cylinder hydraulic cone crusher, and the most popular one is the Symons cone crusher.

The most popular cone crushers

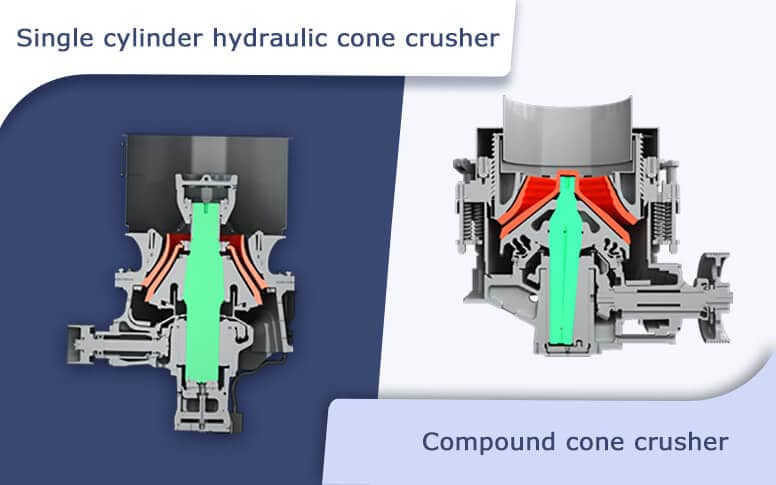

The structure of single-cylinder hydraulic cone crusher is simple. Its characteristics are the steep cone, high swing frequency, and small eccentric distance. The unique design structure of bottom single cylinder can complete the three functions which can adjust the discharge opening directly, prevent ferric materials, and clear chambers.

Difference in structure of cone crushers

The Symons cone crusher has the hydraulic chamber-cleaning system which can reduce its downtime. This machine adopts the lubrication grease system which avoids the defects of water-supplying and discharging block as well as mixing the water and oil easily. The spring insurance system is an overload protection device, which can make the foreign matter and iron ore go through the crushing chamber without damage.

When the single-cylinder hydraulic cone crusher is working, the motor drives the small gear of the crusher, the pinion drives the large gear, and the large gear assembly drives the eccentric sleeve assembly and the spindle assembly, which are centered on the theoretical vertical line, and rotate in the copper bushing.

The spindle assembly in the eccentric copper sleeve with the center line of the spindle can realize the rotating material being crushed by the swinging inner cone, and the crushed material is discharged from the discharge port.

Difference in working principle of cone crushers

When the compound cone crusher is working, the motor drives the eccentric sleeve to rotate by the V-belt, transmission shaft and bevel gears. The moving cone rotates under the action of the eccentric sleeve. The material is continuously crushed and impacted in the crushing chamber, then the needed size of the material after crushing will falls under the gravity and be discharged from the bottom. Symons cone crusher controls the particle size of material according to reducing the size of the discharge opening, so it is not suitable for ultra-fine sand or sand making.

The technology of single-cylinder hydraulic cone crusher is more advanced and higher efficient to operate. Under the condition of the constant crushing chamber, the maximum feeding size and productivity can keep constant, it has higher output, longer liner life, and lower operating costs. Its mainframe weight is 5700 to 36,300 kg, the weight of Symons cone crusher is 9980 to 43,270 kg, and its volume and weight are smaller than Symons cone crusher. Therefore, it is more convenient and quick to install and transport, as well as lift and change parts.

Comparison of different kinds of crushers

|

Name |

Jaw crusher |

Cone crusher |

Impact crusher |

|

Crushing |

Primary crushing/coarse crushing |

Secondary crushing/fine crushing |

Second crushing/shaping |

|

Structure |

Simpler |

Simple |

Simpler |

|

Volume |

Smaller |

Small |

Smaller |

|

Material hardness |

Medium hardness |

High hardness |

Small hardness (soft materials) |

|

Feeding size |

≤1500mm |

≤300mm |

≤800mm |

|

Discharging size |

20 mm to 50 mm |

5 mm to 20 mm |

10-40mm |

|

Capacity |

1-2200t/h |

12-1000t/h |

30-800t/h |

Slide to the right>>

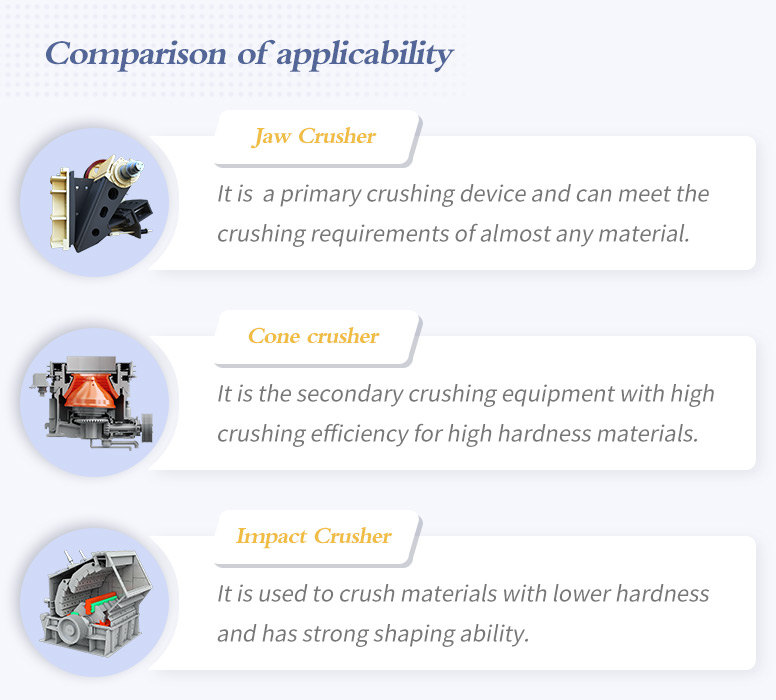

Jaw crusher, cone crusher and impact crusher are the mainstream crushers used in mining industries. Jaw crusher and cone crusher are the classical laminated crushers, and also the most popular crushers, while impact crusher adopts impact crushing principle. In general, jaw crusher is used as the primary crusher, and cone crusher and impact crusher as the secondary. And they always combine with each other in the whole crushing line during the crushing process.

Different crushing principle of jaw crusher, cone crusher and impact crusher

Jaw crusher and cone crusher adopt the laminating crushing principle, known as extrusion crushing principle. Although the crushing actuators are different, the nature of crushing does not make much difference.

During the crushing process, the cone crusher adopts the extrusion between the mortar wall and the crushing wall, and the jaw crusher adopts the extrusion between the mobile jaw and the fixed jaw.

Impact crusher adopts the impact crushing principle, and materials are impacted and crushed between hammer and impact plate. Due to the frequent impact, the wearing parts are easy to damage, so impact crusher has a high requirement on the wear-resistance materials.

The jaw crusher, cone crusher and impact crusher are widely used in a variety of materials, but they have different applicability. The jaw crusher can almost meet the requirements of all materials.

Different applicability of jaw crusher, cone crusher and impact crusher

Cone crusher also has the wide applications, ans it can crush high-hardness materials in high efficiency. However, impact crusher is generally used for crushing soft materials such as limestone because its crushing principle and wear-resistant parts, and impact has a good performance in shaping.

When choosing crusher machines, a comparison should be conducted according to different situations. Generally, jaw crusher is used for primary crushing, and for second crushing or fine crushing, a large ore-dressing plant always chooses the cone crusher, and a medium or small plant chooses the impact crusher.

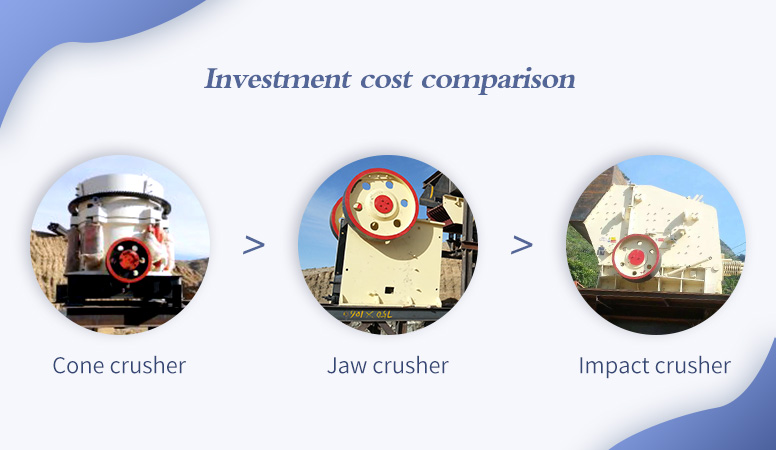

Investment cost of different crushers

Generally, jaw crusher is suitable for all kinds of crushing lines, and it is relatively cheaper than cone crusher because of the large market. Though impact crusher has a cheap price, it has several wear-resistant parts such as hammer and impact plate, which should be replaced after several times uses, so impact crusher has a high using cost.

Although cone crusher is relatively expensive, the wear-resistant parts have long service life to avoid the worries of changing parts frequently. Therefore, cone crusher has higher performance-price ratio than impact crusher in the long run.

HXJQ, as a professional cone crusher manufacturer for 40 years

HXJQ as a professional cone crusher manufacturer has produced crushers for more than 40 years, and we have the crushers with the lowest cone crusher prices and highest quality. If you have any problems in the selection of equipment, please timely consult HXJQ, there are experts who will guide for you in the whole process and choose the most suitable, cheapest, and best-performance equipment for you.

LOOKING FOR MOBILE JAW CRUSHER OR SERVICE?

© CopyRight: Henan Hongxing Mining Machinery Co.

Privacy PolicyThank you for your

information.

The reasons for all kinds of reasons, you can not

imagine the reasons, you said strange is not

strange,

is not to let you submit, collapse?Thank

you for your information.

7×24 online

Chat Online