Introduction

In the past decades, infrastructure construction has promoted the development of steel and played a huge role in economic take-off in Vietnam. However, limited by the beneficiation techniques and processes, the production of steel can't satisfy the requirements of construction. Vietnam has to import a large amount of steel from other countries, while many domestic iron ore reserves can't be developed and utilized reasonably. There are many iron ore reserves in Vietnam and the most common types of iron ore are magnetite, hematite, siderite, limonite and high-sulfur-phosphorus iron ore.

5 types of common iron ores in Vietnam

Most of the iron mines are located in the northern regions and all are distributed in the coastal areas. Vietnam's iron ore has an outstanding advantage of high grade which can save a lot of beneficiation processes and bring more development value. Based on the common types of Vietnam's iron ore, this article will analyze the common beneficiation techniques of the several iron ores, hoping you can get some ideas for your project.Beneficiation techniques of magnetite

Magnetite accounts for 60% of the total reserves of iron ore in Vietnam. Compared with the iron ore required in industrial production, magnetite has a lower grade and high exploitation cost. The Beneficiation process is guided by the principles of "more crushing and less grinding", "more energy-saving and low costs". In general, the crushing process consumes about 8% to 10% of the whole energy consumption, and grinding process accounts for about 45% to 55% as well, among which the power cost, and the costs of mill's balls and liner accounts for 90% of the beneficiation fees. The common beneficiation techniques of magnetite are wet magnetic separation and dry magnetic separation.Wet magnetic separation

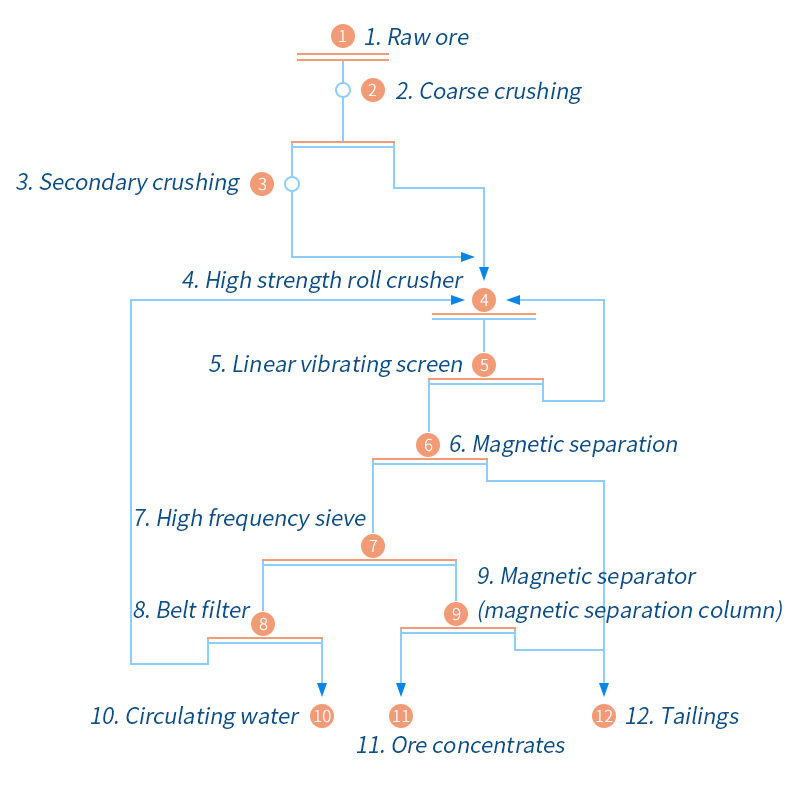

Magnetite iron ore processing flowsheet--wet magnetic separation process

- 1Iron ore is sent into the jaw crusher for primary crushing and then sent into the vibrating screen for screening, and the mesh size is controlled in the range of 35 mm to 75 mm. The materials on the screen are sent into the crusher for medium crushing and then sent into the ball mill for grinding.

- 2After grinding, the materials are sent into the magnetic separator by conveyor for wet magnetic separation, controlling the magnetic field strength at the range of 120-300 mT.

- 3After magnetic separation, send the wet ore into the high-frequency vibrating screen and control the mesh size of 0.1 mm to 0.5 mm.

- 4And the materials larger than the screen pole are sent into the ball mill for grinding after drying by the vacuum belt filter. The screened materials are sent into the magnetic separator to get the concentrates.

Dry magnetic separation

Dry magnetic separation keeps the first step of wet magnetic separation and,- 1After primary and secondary crushing, the ores are sent into the classifier to classify the particles of different sizes.

- 2After classifying into large particles, medium particles and fine particles, the large particles are sent into the ball mill or secondary crusher by bucket elevator for crushing.

- 3Medium particles are sent into the dry magnetic separator, and control the magnetic strength in the range of 1200 GS to 3000 GS.

- 4Fine particles are sent into the dry magnetic separator, and control the magnetic strength in the range of 600 GS to 1200 GS to get concentrates.

Beneficiation techniques of hematite

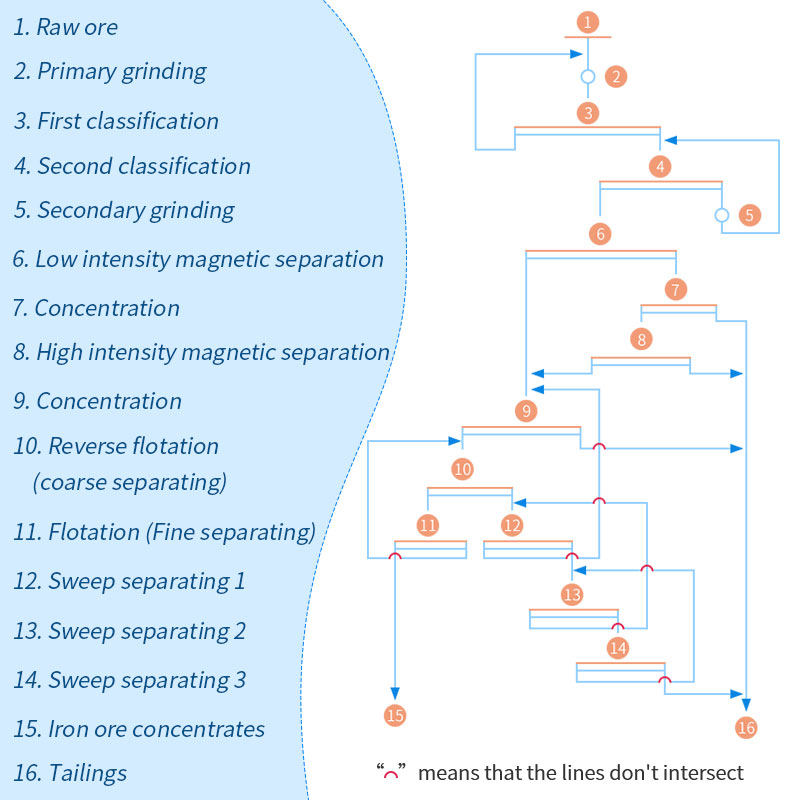

The main beneficiation processes of hematite are:- aProcess 1: continuous grinding → low-intensity magnetic separation → high-intensity magnetic separation → anionic reverse flotation

- bProcess 2: stage grinding→ gravity separation → magnetic separation → acid reverse flotation

- cProcess 3: continuous grinding → low-intensity magnetic separation → high-intensity magnetic separation → acid flotation

- dProcess 4: continuous grinding → low-intensity magnetic separation → high-intensity magnetic separation → cationic inverse flotation

| Process | Grade % | Recycling rate of iron % | ||

| Raw iron ore | Concentrates | Tailings | ||

| Process 1 | 28.97 | 65.33 | 8.70 | 80.72 |

| Process 2 | 29.48 | 65.95 | 11.04 | 75.45 |

| Process 3 | 29.13 | 64.79 | 9.70 | 78.45 |

| Process 4 | 29.16 | 65.22 | 9.69 | 78.28 |

Slide to the right>>

According to the above table, it can be seen that continuous grinding → low-intensity magnetic separation → high-intensity magnetic separation → anionic reverse flotation process can achieve the highest iron recycling rate.

Hematite iron ore processing flow

Process one requires fine grinding, which makes the ore ground to the particle size of all the basic monomers for separation by continuous grinding, preventing re-grinding of the stage grinding process and saving more energy. At the same time, with the increase of mining depth, the FeO content in ore changes greatly. Because high-intensity magnetic separation and anionic reverse flotation have strong adaptability to the fluctuation of FeO content, the whole process can adapt to the change of FeO content to the maximum extent.Beneficiation techniques of siderite

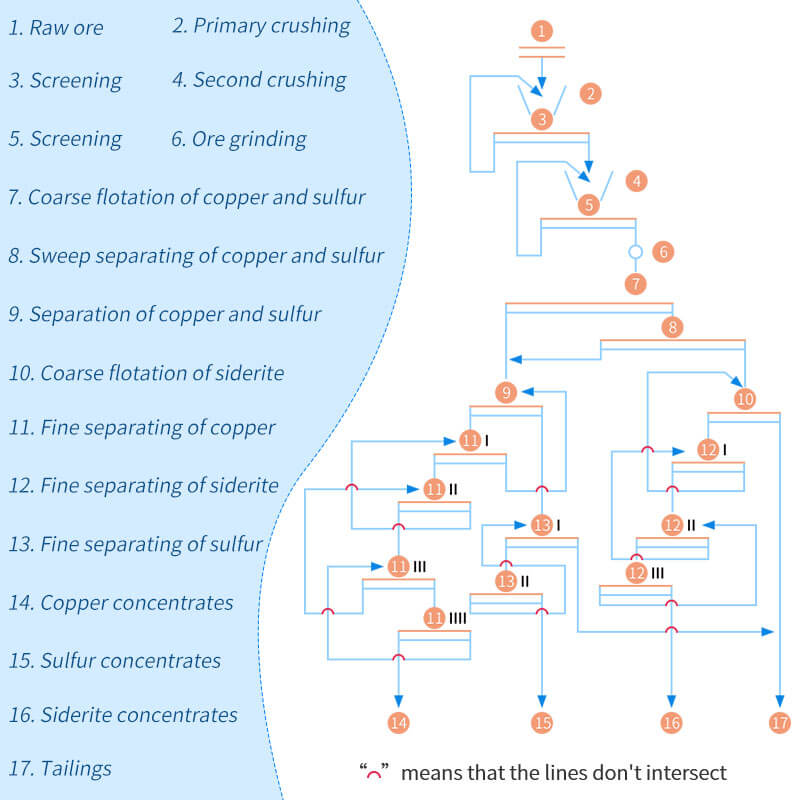

Siderite is one of the carbonate minerals, and its iron grade is greatly improved after calcinating. But it also costs a lot of cost during the calcination process. At present, the most advanced beneficiation technique of siderite is bulk flotation, which can highly improve the recycling rate of iron and get some copper concentrates and sulfur concentrates, and the detailed process is as follows:

Siderite iron ore processing flow chart

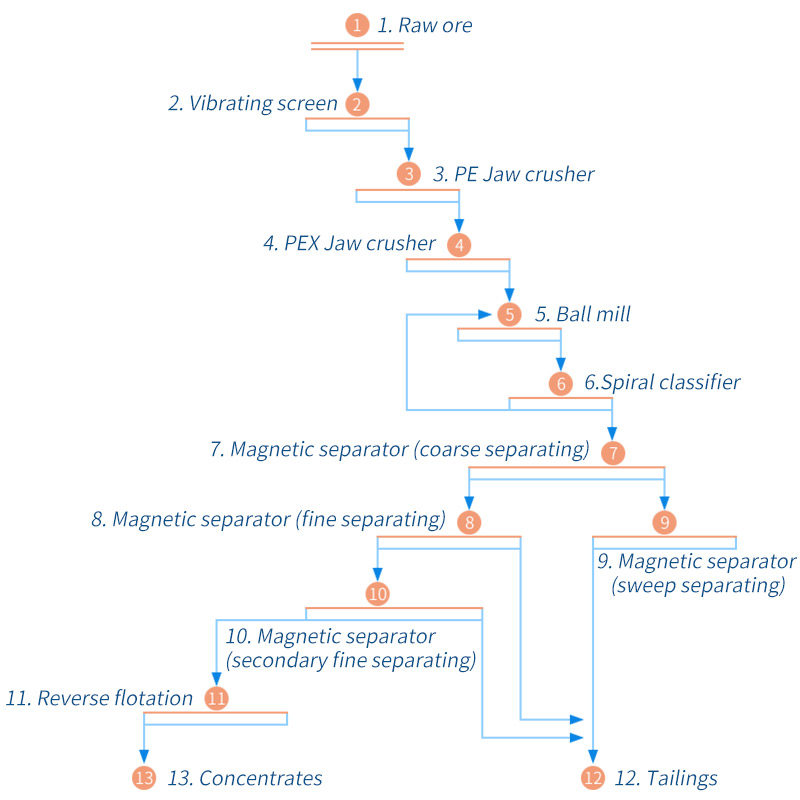

Beneficiation techniques of limonite

Theoretically, being rich in crystal water, limonite has a low grade. The iron concentrates can hardly be reached up to 60% according to physical dressing. Meanwhile, limonite is easy to be sliming and seriously loses, which results in a lower recycling rate of iron. Currently, the most common beneficiation technique of limonite is high-intensity magnetic separation, which has a bad effect on iron recycling. The main reasons are as follows:- The grinding particles are hard to control.

- The iron loss is serious during the sliming process.

- The recycling grade of iron is lower.

Limonite iron ore processing method

Crushing and grinding

Limonite is crushed into the size of 3 mm and sent to the ball mill for grinding into 200 mesh, setting the pulp density of 50% to 60%. After screening by the high-frequency screen of 200 mesh, the pulp density is adjusted into 20% to 25%, and the larger iron particles are sent back to the ball mill for further grinding.Gravity separation

Send the pulp density into the spiral chute for coarse separation, first and secondary fine separation:

HXJQ spiral chute

- 1 Coarse separation: the slurry was deslimed, and the slurry discharged from the concentrate and middle discharging port was adjusted to a concentration of 15% to 25%, and the sludge and part of the tailings at the outer edge of the spiral chute were discharged into the tailings pond.

- 2First fine separation: the pulp is deslimed and selected, the concentrate is intercepted from the concentrate port, and the pulp discharged from the middle discharging port is adjusted to a concentration of 15% to 25%, and the mud and part of the tailings at the outer edge of the spiral chute are discharged into the tailings pond.

- 3Secondary fine separation: the pulp is deslimed and finely selected again. The concentrates are intercepted from the concentrate port, and the pulp discharged from the middle discharging port is adjusted to a concentration of 15% to 25%.

Reverse flotation

Reverse flotation is started and the mud and part of the tailings at the outer edge of the spiral chute are discharged into the tailings pond. Add about 100g to 200g of inhibitor and 100g-150g collector into the adjusted pulp, stir for 2 to 3 minutes, and take reversely flotation for 10-12 minutes at normal temperature and PH=7 to obtain high-grade limonite concentrates.Beneficiation techniques of high-sulfur-phosphorus iron ore

Sulfur and phosphorus associated with iron ore is more harmful to iron ore' applications, and when processing and smelting iron ore, sulfur and phosphorus are more difficult to remove. When there is a certain amount of sulfur and phosphorus in the iron and steel, it will seriously damage the mechanical properties of steel products. The global professionals of iron mine beneficiation have been doing the research work of removing sulfur and phosphorous from iron ore. The experiment shows that the highest grade of iron concentrate can be obtained by the process of stage grinding → high-gradient strong magnetic separation → discarding tails → flotation to remove phosphorus → reverse flotation.

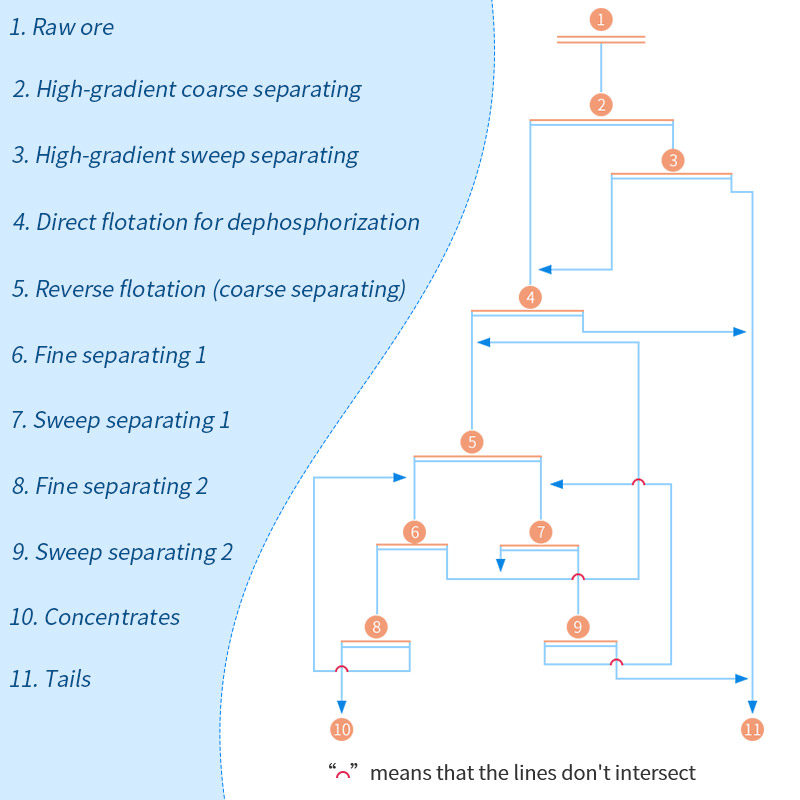

Beneficiation techniques of high-sulfur-phosphorus iron ore

Conclusion

Vietnam's iron ore is widely distributed and abundant in reserves, but the comprehensive processing technology and economic level are relatively lower, resulting in the low utilization rate of iron ore resources, and even a large number of iron minerals are not developed. Choosing suitable ore processing technology and special production equipment can not only give full play to the advantages of iron ore resources, but also be able to deeply explore the value of different grades of iron ore.

HXJQ dressing equipment factory

With more than 40 years of development, Hongxing Mining Machinery as a professional processing equipment manufacturer produces various mining machines by mature advanced technology. And all the machines' quality can be guaranteed. All the dressing equipment adopts innovative technology and improves the backward equipment to reduce the energy consumption in the production process. The equipment is made of new wear-resistant material, which can effectively extend the service life of the equipment and save production resources.

Chat Online

Chat Online

Send message

Send message