Unconsciously, the March 15 International Consumer Rights Day has passed more than half a month. With its unique design and excellent quality, HXJQ has passed the 3.15 quality test as expected, which makes every staff of HXJQ proud. This is not only significant for HXJQ Group, but also for customers who choose us. As we all know, what is more important than product quality from the perspective of customers? Thus, HXJQ who has always put the quality in the first place could help those who choose us make a sound foundation toward success.

What is HXJQ doing to guarantee the quality

Mining machinery belongs to heavy industry with high capital and technology intensity. Thus, the improvement of technology is crucial to the development of the industry. Now the whole industry is caught in a state of many engineering machinery OEMs and few development in R&D, for the investment in innovation and research in mining equipment is huge but the result is not certain. If you don’t innovate independently, how to make sure offer the best quality products to our customers and how to catch the market share in the mining machinery industry? The answer is obvious that we must update the technology and arm ourselves with exquisite expertise.

Innovation is the first impetus. The HXJQ Group invests a large amount of money each year only for the R&D of the products. The results of research and development are reflected in many of our professional achievements, also in the update iteration of our products. On the way to innovation, the HXJQ Group has never stopped.

In order to ensure that every mechanical device is in its best quality, the HXJQ machinery always strictly controls the quality for creating high-quality mining machinery and equipment in every detail. And the followings are the exact measures we have been taking.

Firstly, the parts of the crusher are made of wear-resistant materials imported from Germany. The toughness and sturdiness are greatly enhanced, so it is not easy to wear and be damaged by the external environment.

Secondly, after continuous innovation, HXJQ Machinery has developed a set of advanced production and processing technology in more than 40 years of production experiences. As a result, we have the advanced manufacturing process, the high efficiency, and the powerful technology.

Thirdly, with complete production and processing equipment, reasonable configuration, we are confident in providing an important guarantee for the development of high-quality, high-efficiency mechanical equipment.

Lastly, HXJQ pays great attention to the detail. We care about every step of manufacturing for more excellent products. We examine for 2-4 times after the completion of each part of the mechanical equipment to ensure zero failure.

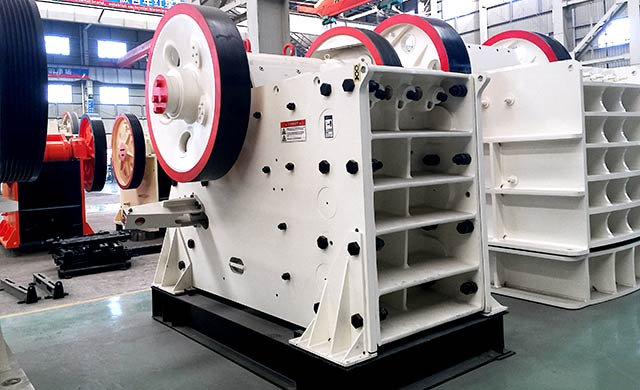

Taking jaw crusher as an example

CJ series jaw crusher has an excellent performance introduced by HXJQ Machinery according to the needs of customers. In the production process, advanced technology, unique design and high-quality material selection ensure a high quality and efficiency of the product. It is different from the traditional jaw crusher in terms of the motion parameters, frame structure and adjustment mode which are greatly Improved. The most important thing is that the CJ series is better than traditional machines in terms of workmanship, so as the crushing efficiency.

Non-welded detachable frame: we adopt cylindrical pin connection among the side plate of the frame, the front plate and the rear crossbeam to make the bolts fastened, which overcomes the shortage of stress concentration in the welding frame and is more robust and reliable. The detachable structure facilitates transportation and installation, especially for downhole installation and transportation. Segmented design facilitate transportation when brought to the ground for operation.

Optimized motion parameters: excellent motion parameters enable the materials to be crushed in the upper part of the crushing chamber, and the stroke in the lower part of the crushing chamber is larger, as well as the crushing ratio.

Large bearing design: Compared with the previous jaw crusher of the same specification, the bearing specifications are increased and the service life is extended. The specifications of the four bearings of the moving plate are the same as those of the frame, which reduces the types of spare parts.

Wedge-type discharge opening adjustment mode: Compared with the traditional insert-type adjustment mode, the new type one adopts the wedge-type discharge opening, which reduces the labor intensity and downtime of workers. The users can choose to install the hydraulic adjustment discharge port device as needed, making the adjustment of steel plates easier. Besides, the brackets are made of high-strength steel plate material, and the crusher is bent and deformed when overloaded to prevent the key parts of the crusher from damaging. Compared with traditional cast iron brackets, it is light and easy to replace, avoiding the steel iron plates falling off and damaging the conveyor.

Integrated motor base structure, integral steel frame base: integrated structure of generator base and mainframe simplifies its installation and saves space. The whole machine is placed on the base of steel frame, and the generator and base are connected by shock pad, which means the impact is small.

The CJ series jaw crusher introduced by HXJQ Group takes up less space, has a larger crushing ratio, and runs more smoothly. It has more advantages in transportation installation and maintenance adjustment, especially suitable for fixed crushing lines and mobile crushing plants.

What is HXJQ doing when serving customers

In the mining field, in order to win the trust of customers before signing the contract, the other manufacturers will blow their own after-sales to let down customers’ guard. However, customers tend to be disappointed at the unsound after-sales system and even lose confidence in any other manufacturer, which has a bad influence on the mining equipment manufacturers.

All staff of HXJQ Group have been treating the customers as God, committing to offering a strict and reliable service on every production process. Apart from equipment and after-sales service, what customers real need is a credit-consuming and complete service system. Our standard for measuring all works is to satisfy customers and our goal is to get customers’ trust.

Online and offline communication: You can get the contact information by browsing the website, or contact customer service to leave your contact information, we will get in touch with you in time.

Tailored or customized: Professional team customize cost-effective solutions, making detailed production equipment planning to achieve your expectations.

Special vehicle transportation and distribution: The supply is sufficient and fast to reach the site, ensuring timely input into operation, shortening the time cost for customers.

Customer acceptance installation and commissioning: After the equipment is qualified, our company will send professional engineers to the construction site for commissioning and installation to ensure the equipment can run efficiently.

Quick supply of genuine accessories: We have established a complete spare parts supply system, a large spare parts supply warehouse, and reserved millions of professional spare parts with complete models. No matter when and where the customer calls for the equipment, we will quickly supply high-quality accessories to ensure that customers get the spare parts needed for use and maintenance in the first time.

Exquisite team of technical experts: high-quality, professional service team, standardized service processes, diversified service channels and perfect customer return visit management mechanism, comprehensive and systematic training system, provide comprehensive technical support to ensure every customer's project being stable.

Strategic layout of service network: Sales and service outlets are spread all over the world. Thousands of skilled and experienced service engineers who know about the parts exactly are ready to provide you with best service.

HXJQ act on what we say

The brand HXJQ is cast the value qualities of keeping our original heart of being a great craft manufacturer, bearing the crucial test of the market, and withstanding the praise of the vast users. It is the stable quality that makes HXJQ go farther. HXJQ always do what we commit.

Free consultation: Quick response to technical consultation within 30 minutes

Quick installation: The service engineer will complete the installation and commissioning within 1-2 days.

24h customer service: 365 days a year to receive service requests

Perfect after-sales: Implement multi-year tracking service for the equipment sold

Technical training: Our company provides free technical training. After the installation and commissioning, the buyer's operator will be trained for no less than 10 days at the buyer's site or at the seller's domestic training and repair center until the operator reaches the basic use of the equipment. The training content is as follows:

Operating procedures of switching machine training;

The meaning of the panel and control parameters, the training of the parameter selection range;

Cutting control software operation training;

Basic cleaning and maintenance of the machine;

Common hardware troubleshooting;

Problems that should be noted during operation;

In addition to this, the user is provided with relevant technical support for the products they produce.

Listening to the customer's evaluation of the operation quality of the equipment, the satisfaction degree of the production status of the production line, the acceptance degree of the replacement frequency of the wearing parts is what HXJQ has been doing. Helping the customer to solve some current problems, recording the imperfect experience encountered by the customers one by one are what HXJQ is doing. What do you worry about when getting such service?

Innovation drives development, and quality creates brand HXJQ. The company has 132 technical patents and the products have passed ISO9001, CE and GOST international quality system certification. What’s more, the “HXJQ Brand” machine has won many awards such as “China Famous Brand” and “Top Ten Brands of Chinese Mining Machines”. Reliable and stable quality makes the company's sales volume and various comprehensive economic indicators rank among the top in the domestic industry. Tens of thousands of users are spread all over the country and the products are exported to more than 100 countries.

Chat Online

Chat Online

Send message

Send message