Steel is an essential material used in our modern life and also the cornerstone of industrial development and plays an important role in economic growth.

The main material required in steel making process is iron ore. According to the incomplete statistics, 98% of the iron ore mined daily is used to make steel. The global steel industry currently produces 1.7 billion tons of crude steel annually and consumes about 2 billion tons of iron ore.

However, with the limited iron ore resource, effective use of natural resources is the key to sustainable development. Using the reasonable techniques and advanced processing equipment will greatly improve the utilization rate of iron ore resources, thus extending the mining life of iron ore.

In last blog, we have introduced a lot of iron ore processing methods and techniques. And this article will recommend you 10 types of iron ore processing equipment, and share you 4 tips to choose suitable machines and manufacturer, hoping you can get some ideas.

Here are the 10 types of most popular iron ore beneficiation machines.

| Model | Function | Capacity | Price |

| PE Jaw crusher | Coarse crushing | 1-2200 t/h | $ 3,000-200,000 |

| PEX Jaw crusher | Fine crushing | 8-105 t/h | $ 2,000-30,000 |

| Ball mill | Grinding | 0.65-615 t/h | $ 10,000-300,000 |

| High-frequency screen | Screening | 15-48 t/h | $ 1,000-3,000 |

| Spiral classifier | Classifying | 20-1785 t/d | $ 1,000-70,000 |

| Magnetic separator | Separating | 10-280 t/h | $ 1,500-13,000 |

| Flotation machine | Separating | 0.18-20 m³/min | - |

| Filter Press | Dewatering | Depends on the plate | $ 1,000-7,000 |

| Dryer | Drying | 1.9-76.0 t/h | $ 4,000-300,000 |

| Concentrator | Concentrating | 0.7-378 t/h | - |

Slide to the right>>

*All the prices are referred from the Internet, and for more information, please consult us by email or online service.

Crushing process

PE Jaw crusher

PE jaw crusher, referred to as PE crusher, is the most important crushing equipment in mineral processing equipment. The dressing process always follows the principle of "more crushing and less grinding". Therefore, a good primary crushing equipment is crucial to the whole process.

PE jaw crusher is suitable for the coarse crushing of iron ore, and its discharge port can be adjusted which makes the crushing specifications are diversified.

Compared with traditional jaw crusher, PE crusher has the following advantages:

-

The E-shape machine frame makes a more stable operation of PE jaw crusher, bringing less vibration and noise.

-

The jaw plate is made of high manganese steel, greatly improving the wear-resistance.

-

The discharging size is equipped with the hydraulic cylinder or screw rod, which makes adjustment of discharging port more convenient and simpler.

-

The crushing cavity is designed to the "V"-type, to improve 30% to 50% of the production.

PEX Jaw crusher

PEX jaw crusher, also known as the fine jaw crusher, is an ideal equipment for iron ore crushing.

PEX jaw crusher adopts high manganese steel frame, which makes the producing process more reliable and firmer;

The scientific structure and compact and reasonable connection between components make the installation, repair, and maintenance more convenient;

The unique flywheel design enhances the load-bearing of the equipment, which can effectively reduce the vibration of the equipment in the production process and make the machine run more smoothly;

The new adjustment method of discharging port brings wider finished product size, and help to achieve the production with various particle sizes, to meet the production needs of different users;

The design of the crushing chamber is optimized to eliminate the blind crushing zone, which can realize a large amount of material handling and efficient production.

Grinding process

Ball mill

The ball mill is the key equipment for the grinding of iron ore after crushing, and the grinding process is the important process of iron ore sorting.

Ball mill can grind iron ore from 25mm to 150-250 mesh, and with high grinding efficiency, it reduces more load and grinding cost.

Advantages of iron ore ball mill:

-

The iron ore ball mill reasonably increases the number of grate cracks, greatly improving the ventilation area, and having a strong anti-blocking self-cleaning function.

-

The screening plate of iron ore ball mill has certain screening pressure, which can be adjusted simply according to the requirements of fine powder of the mill; in addition, the screen space is designed reasonably, which can effectively improve the screening efficiency of materials.

-

The iron ore ball mill scientifically adjusts the grading scheme of the steel ball according to the size, and composition of the materials to be ground, so as to make the particle size of the materials more even.

-

The iron ore ball mill adopts a closed system to achieve less dust and low noise, which greatly reduces the harm to workers and the cost of enterprise environmental protection.

Iron ore dressing process

Magnetic separator

According to the characteristics of iron ore, Hongxing Mining Machinery has specially developed iron ore magnetic separator, which has the following characteristics:

1. Saving more electricity.

It needs only a small amount of transmission power consumption in the process of operation, which can save electricity 70%-80%.

2. Lightweight of the machine.

The equipment weight is light, and its capacity is large which is generally 2 times of the strong magnetic separator.

3. Less investment in infrastructure.

Due to the lightweight of the equipment and less auxiliary equipment, infrastructure investment can save 20% to 25% compared with the strong magnetic separator.

Flotation machine

For iron ore, especially hematite, the selection of the flotation machine is very important.

There are three common flotation machines for iron ore in the market: mechanical stirring flotation machine, inflatable stirring flotation machine, and inflatable flotation machine.

Comparison of advantages and disadvantages of three flotation machines:

| Model | Advantages | Disadvantages |

| Mechanical stirring flotation machine | Less auxiliary equipment, and simple operation and maintenance | More power consumption, high wear and tear |

| inflatable stirring flotation machine | Less power consumption, and less wear | An additional inflator system is required |

| Inflatable flotation machine | Simple structure and low production cost | The attached inflator is easy to form calcium |

Slide to the right>>

In view of the above comparison, it is recommended here that the gas-filled agitator flotation machine, in view of the characteristics of iron ore, the gas-filled agitator flotation machine can properly adjust the speed to prevent material sludge. Although it is necessary to configure the pneumatic system in the early stage, it can bring great economic benefits due to less wear and tear in the later use and low cost.

Classifying process

High frequency screen

Iron ore high-frequency screen adopts new principle design, which is a new high-efficiency screen equipment.

The shaker drives the screen surface through the drive mechanism for high frequency vibration and screen box static.

The vibration system is designed to work in the near resonance state, the whole machine is supported by vibration reduction so that the ground does not bear the dynamic load.

There is no need to make a foundation for the high-frequency screen, and it can work normally by installing on the solid flat ground or ordinary steel structure platform.

During the classification of iron ore, the vibration frequency of the screen surface is 50Hz, the amplitude is 0 to 2 mm, and the vibration intensity is 8 to 10 times of the acceleration of gravity, which is 2 to 3 times of the vibration intensity of the general vibrating screen.

Therefore, high-frequency screen can work normally without blocking the hole. Meanwhile, the screening efficiency is high, the processing capacity is large, and the grading particle size can reach 0.074 to 1 mm.

Spiral classifier

Iron ore spiral classifier (iron ore classifier) is a new classification equipment which can be used in the ore dressing process of iron ore pulp for efficient and accurate classification.

It has the features of simple structure, reliable performance, easy to operate and other advantages. The fineness of the finished product can be easily adjusted by the size of the classifier inclination Angle and the rotating speed of the spiral plates.

The machine base adopts channel steel, and the rest of the parts are made of steel plate. The water injection side and the shaft head of screw shaft are made of cast iron to improve the wear-resistance.

When the solid particles are different in size, shape and proportion, the settlement performance in the liquid is different.

According to the principle, a spiral classifier combines into a closed cycle process with ball mill in the beneficiation production. The minerals of the required size are discharged as finished products from the overflow end to the next step and the coarse particles are returned to the ball mill for regrinding.

Dewatering process

Filter press

Filter press is the most common dewatering equipment in magnetic separation of iron ore.

In the flotation process, the pulp water content of iron ore can be up to 70%-80%. During the dewatering process, filter press not only can greatly reduce the humidity of iron ore (water content can be reduced to 15%) but also can greatly improve the production efficiency and concentrate purity.

Recommended here are the fan filter press, belt filter press, and automatic box filter press.

The advantages and disadvantages of the three are compared as follows:

| Model | Advantages | Disadvantages | Suitable for |

| Fan-type filter press | Simple structure, small coverage of land and low investment | Small capacity | Small dressing factory |

| Belt-type filter press | Simple structure and operation, good performance and can work continuously | Large coverage of land | Middle or small dressing factory with a high capacity requirement |

| Automatic hydraulic filter press | Simple operation and maintenance and high working efficiency | Expensive | Large dressing factory |

Slide to the right>>

Concentrator

The concentrator is a device for settling and dehydrating the processed concentrates, which can effectively improve its purity.

Concentrator equipped with complete automatic control facilities can realize automatic production, improve the filtration and compression rate of pulp and the material handling capacity.

The iron ore thickener adopts deep central feeding, which reduces its settling height and the kinetic energy of solid particles.

The rake frame is a structure of connecting rod, which makes a free settling speed, a faster condensing and compaction process, and an increase of processing capacity by 30% to 50%.

The machine is equipped with a central agitator so that the material will not consolidate when the concentration of bottom flow increases.

In case of long downtime or failure, the central agitator can also be used to clean the machine without draining water, which is convenient for daily maintenance and repair.

Dryer

The dryer is the main equipment to dehydrate and dry the purified concentrate.

At present, the common iron ore dryer on the market mainly has three kinds: rotary dryer, net belt dryer, vertical dryer.

Among which the rotary dryer stands out among many ore dryers for its simple structure, wear-resistant material and super working efficiency.

The barrel of rotary dryer is welded by steel plate, and the feeding and discharging covers are equipped with sealing plates to prevent heat emission and reduce heat loss.

At the same time, the outside of the barrel can be protected by insulation cotton and galvanized board, so as to achieve rain prevention, corrosion prevention, thermal insulation.

Theoretically, the humidity of iron ore processed by a rotary dryer is 0, which greatly improves the utilization rate of iron ore and saves more processing costs.

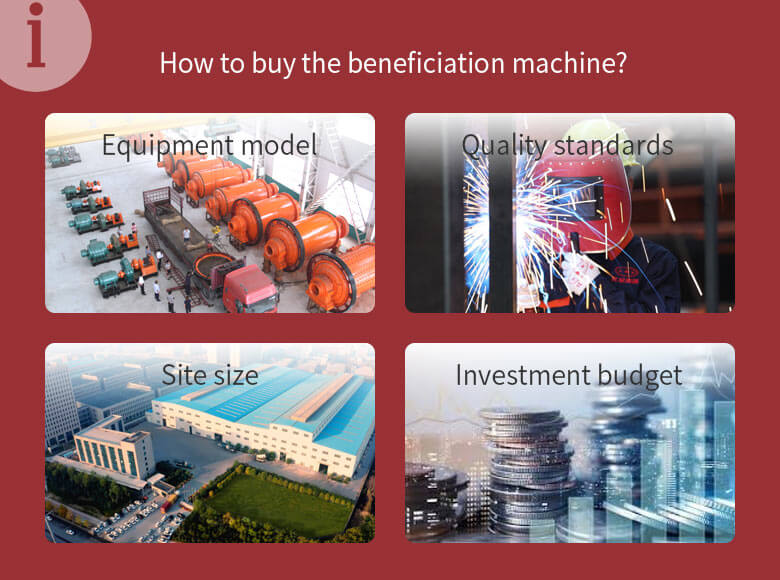

How to buy the beneficiation machine

In the selection of dressing equipment, customers should consider their own materials, product characteristics and the required production capacity firstly for strict selection so that to buy suitable and reasonable equipment.

When purchasing iron ore processing equipment, the following points should be paid attention to:

Equipment model

Before buying iron ore dressing equipment, model selection is a very important factor to be considered. Users need to consider whether the production capacity of this type of machine is within their capital budget, so as to avoid too large a model and lead to the waste of funds.

After all, the size of the equipment model is one of the main factors influencing its price. The larger the model, the higher the price of the equipment will be, which will also lead to higher production costs.

Therefore, it is recommended that users choose the model that matches the production requirements.

Quality standards

The quality of the equipment is the main factor affecting the performance of the equipment. The higher the quality of the equipment, the longer the service life and the more value bring to customers.

In the process of buying the machine, customers should pay more attention to the machine’s materials to avoid being cheated.

Site size

The size of the site is one of the criteria for the selection of the iron ore dressing machine. If the site is large, the selection of smaller models and equipment will certainly not meet the requirements of production. In addition, if the business needs to be expanded later, the machine should be in a large model.

Especially in the purchase of dryer, ball mill and other equipment, customers should fully consider the production site, and communicate with the manufacturer actively so that to make good cooperation.

Investment budget

It is very necessary to calculate investment in advance. The price of the different equipment is totally different, and the same equipment in different sizes also has different prices. It is recommended that users make budget funds before the purchase of equipment to select more suitable and relatively inexpensive machines.

Manufacturer recommended

As a leading mining machinery manufacturer in China, Hongxing Mining Machinery has over 40 years of experience in design, production and sales. It is a large-scale joint-stock enterprise integrating scientific research, production and sales.

Over the past 40 years, Hongxing Mining Machinery has always kept in mind the original intention, insisted on the quality of products as the foundation, customer satisfaction as the ultimate goal, adhered to the responsible attitude for each product, and dedicated to customer service.

After more than 40 years of vigorous development, Hongxing Mining Machinery's product quality, sales volume and various economic indicators ranked at the forefront of China's mining machinery manufacturers, and the products have been sold to more than 100 countries and regions and won numerous praises.

Chat Online

Chat Online

Send message

Send message