PRODUCTION CAPACITY: 5-2200 T/H

FEEDING SIZE: 120-1500 MM

OUTPUT SIZE: 10-400 MM

Processing Materials: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, glass, cement clinker and some metals.

Download Jaw Crusher PDF

Download Jaw Crusher PDF

Download PDF

Download PDF

Firstly, they differ in the working principle.

For jaw crusher, the driving power of the generator leads to the movement of the swing jaw and of the eccentric shaft and then the materials are crushed.

While the working principle of cone crusher is laminated crushing. The rolling wall continuously moves toward the broken wall, and the material between the two is squeezed to be pulverized.

Here is the working principle of impact crusher. The toothed counter-back plate rebounds and falls freely after the material reaches the top of the vortex breaking chamber and then hits and crushes constantly with subsequently upward impacting materials.

In actual production, both of them have many differences, as follows:

Jaw crusher processes the hardest and medium-hard stones as the first crusher, and impact crusher and cone crusher can both act as secondary crushing devices, but the hardness of the two broken materials is not the same.

Cone crusher mainly crushes some harder materials, such as granite, basalt, river pebbles and so on, while impact crusher is used to crush the materials that are not so hard, such as limestone, limerock, etc. These materials above can be crushed firstly by jaw crusher.

The discharge size of jaw crusher is widely adjusted from 10-400mm, which is coarser than that of the second-stage crusher. But the discharge sizes of the secondary crushers are not the same. Generally, the discharge granularity of cone crusher is finer than that of impact crusher.

In the actual production, jaw crusher can be used wisely in mining, construction, building materials, etc. But cone crusher is more often used in ore processing and impact crusher in construction and building material processing.

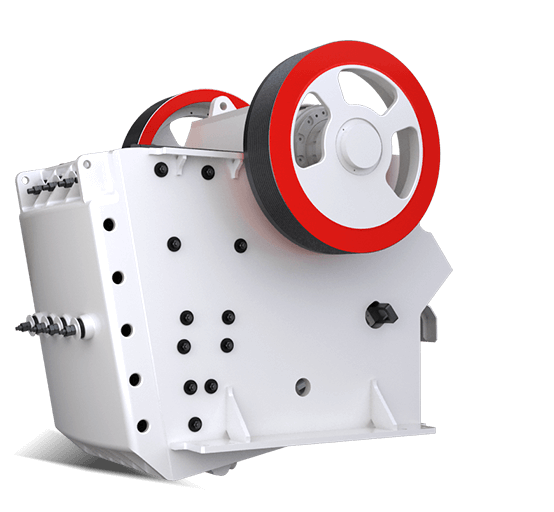

The jaw crusher is a kind of early crushing device. With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building materials, electricity, transportation and other industries.

The working mode of this series of crushers is a curved extrusion.

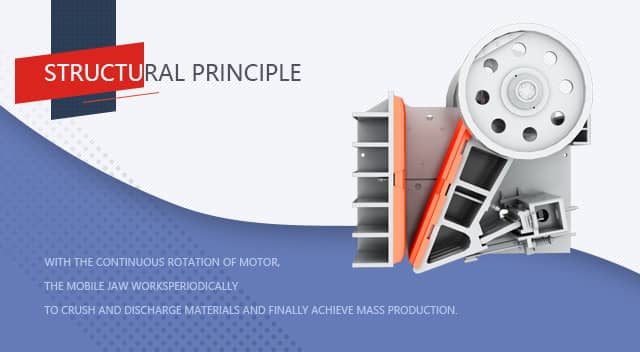

The working principle is: the motor drives the belt and the pulley, and the mobile jaw is moved up and down through the eccentric shaft. The angle between toggle plate and mobile jaw increases when mobile jaw moves up, thereby the mobile jaw is closer to the fixed jaw, at the same time the materials are crushed or chopped to achieve the purpose of crushing;

the angle between toggle plate and mobile jaw decreases when mobile jaw moves down, the mobile jaw is separated from the fixed jaw under the action of the pull rod and the spring, meanwhile the crushed materials are discharged from the lower mouth of the crushing chamber.

The inertia required to crush the materials is provided by the flywheel, and the eccentric shaft generates eccentric motion which results in the gap getting closed. With the continuous rotation of motor, the mobile jaw works periodically to crush and discharge materials and finally achieve mass production.

Jaw crusher is a kind of heavy-duty machine and therefore require the solid construction. The external frame is usually made of cast iron or steel. The jaws are usually made of cast steel fitted with replaceable gaskets which are made of manganese steel or Ni-hard (Ni-Cr alloy cast iron). Jaw crushers are usually constructed in sections so that they can be transported easily when they are brought underground for operation.

HXJQ Corporation is a global equipment supplier of process solutions for mining industries. We uphold the highest standards for engineering and manufacturing.

In the mining and construction crushing industries, the jaw crusher at the front end of the production line, and its performance directly affects the quality and operation of the whole production line.

HXJQ Corporation has brought new breakthroughs in the production and upgrading of mines and gravel production lines and produced a series of jaw crushers in high quality and high standards with its over 40 years experiences and cases in crushing industry according to the market demand.

As the early crushing device, PE jaw crusher always gains the popularity by users. We will analyze the characteristics, advantages and disadvantages of different types of PE jaw crushers and their investment prospects from different perspectives.

Models: PE-150×250, PE-200×350, PE-400×600

Advantages: Small size, easy to transport and install; Low price, suitable for small investment, small and medium-sized production requirements

of crushing

Disadvantages:Low output, only suitable for small workshops with small investment and small output.

Investment prospects: Small investment in the early stage, small output; slower profit recovery; Suitable for

users with less budget and less production requirements; the investment prospect is general.

Models: PE-600×750, PE-600×900, PE-750×1060

Advantages: Medium size, easy to transport and install; Moderate price, suitable for the medium production of crushing; Chosen by the most users.

Disadvantages: Medium production, can not meet the crushing requirements of a mass of mining materials, not suitable for crushing large mines.

Investment prospects: Less investment, medium output; Faster profit recovery;

The investment prospect is bright.

Models: PE-830×1060, PE-1000×1200, PE-1500×1800

Advantages: Large output and strong crushing capacity; Suitable for crushing large mines.

Disadvantages: Large size, difficult to transport and install; Suitable users are limited; The profit recovery is slower.

Investment prospects: Large investment, large output; Slower profit recovery; Suitable for large, long-term mining; The investment prospect is bright but the users are limited.

According to the table, the medium-sized PE jaw crusher is the most popular among users both in terms of investment prospects and ranges of application. According to the statistics of HXJQ Corporation, PE-600×900 is hottest and very popular among domestic and foreign customers because of its advantages of price, volume, ranges of application, etc.

LOOKING FOR MOBILE JAW CRUSHER OR SERVICE?

© CopyRight: Henan Hongxing Mining Machinery Co.

Privacy PolicyThank you for your

information.

The reasons for all kinds of reasons, you can not

imagine the reasons, you said strange is not

strange,

is not to let you submit, collapse?Thank

you for your information.

7×24 online

Chat Online